How much shipping box do you really need? If you've received a package from Amazon lately, you may have noticed it came in a 23 ECT box. Amazon knows that they can save on shipping costs by using lightweight boxes and reinforcing items with cheaper dunnaging materials to help them shave dollars off of their millions of shipments. For small businesses, this is a great way to save on shipping costs. What secrets about shipping can Amazon and other major-shippers teach small businesses?

TLDR; Companies like Amazon ship with 23 ECT boxes when they can to save on shipping weight and reduce overall waste in their shipping logistics. Though items that need 200# or stronger boxes need to be shipped too, most shipments can be sent in 32 ECT or less without damaging your shipped products. Including smart package handling messaging and adequate dunnage around your item can drop your shipping costs while extending your user journey with marketing messaging.

If you're a small business owner, you know that one of the biggest expenses is shipping costs. Amazon has figured out how to save money on shipping by using lighter boxes (among other strategies). The company ships millions of packages a day, so they know a thing or two about affordably shipping boxes en masse. It all comes down to the weight of your package.

Lightweight products like books or apparel usually don't need heavier-duty boxes. Saving weight on your shipping boxes will bring down your overall shipping costs and create a more sustainable supply chain. Heavy duty boxes are more expensive to ship in freight cost and fuel, leaving a big foot print when your product may not need that much box to protect it.

Smart dunnage solutions can be lightweight and also add security to your shipments, saving you and your customer money. Dunnage also creates an opportunity to add your branding and extend your user journey into the delivery and unboxing process (add call to actions and see your ROI increase).

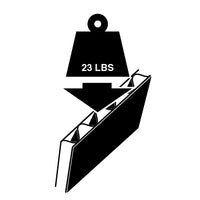

The Edge Crush Test (ECT) finds the strength of a cardboard box in a stacking scenario. A box of 23 ECT strength can withstand about 23 pounds of pressure to its edge, or as demonstrated in figure 1.

A Mullen Burst Test measures how much force a cardboard sheet can take before bursting. A Mullen-rated box of 200# can withstand 200 pounds of force per square inch. See figure 2 for a visual.

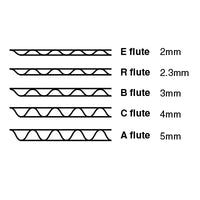

How many box strengths are there? Generally, 32 ECT and 200# boxes are what you will find in store and online. These boxes can handle most shipping, moving and storing needs of businesses or individuals. There are tons of variations of fluting combinations and sizes available for shipping products. To start, how many walls of cardboard does your product need to be secure? There are single wall, double wall and even triple wall cardboard boxes available. Combinations can be made of varying flute sizes, like combining an 'A' and 'E flute' (figure 3) to create an 'AE flute' that meet your burst and crush test requirements for heavy duty shipping needs.

Its important to remember that the Mullen and Edge Crush tests aren't exactly equivalents as they do measure completely different stresses on boxes.

The Mullen test is a better measure for shipping boxes as it addresses the stresses a shipping box might undergo during its journey from your shop to your customer's door step. While shipping is a parodiable part of the supply chain, shipping methods have improved in the years following its implementation of box strength standards with more automated conveyances during handling and shorter trip lengths. Lighter weight boxes like 23 and 32 ECT have a better chance of success in shipping than historically may have been the case.

The Edge Crush Test was developed in the 1990's to create more efficient ratings for palletizing cardboard boxes for storage. This test allows shippers to create max weights for stacking boxes before the load crushes it. Modern shipping and warehousing techniques mean that products are often loaded on pallets and stacked very high for container shipping efficiency. As a result, boxes need to be strong enough to hold not only the weight of the product they contain, but also the weight of any goods on top. The inate strength of vertical corrugated material means 32 ECT boxes are relatively as strong as 200# boxes, but weigh less by using less material. Use the charts below to identify how much box strength is appropriate for your business based on the maximum load per carton.

Shipping boxes and logistics costs are often a large part of your cost of goods. Reducing the cost of your shipping costs for inbound materials will reduce your overall cost of goods or at least allocate more budget to other customizing options to increase the ROI of your packaging.

Choosing a lightweight box: Consider the cost of shipping boxes to your location just to ship to your customer - you pay for shipping twice! Reduce overall shipping costs by choosing a box size that can be shipped affordably as well. The size of product being shipped is usually the primary fixed volume, so when looking for how to reduce box costs, consider going with a thinner box strength like 32 ECT instead of shrinking the overall box dimensions of a 200# strength box reducing your box weight without compromising on box size. Finding a local location for shipping boxes that offers local pick up can cut shipping costs in half for your business (local to north Oregon or Washington state? Pick up your boxes here).

Smart dunnage and protection: If there is concern about the safety of products during shipping, include smart dunnage that secures your items inside the box. Ensure there is space for the dunnage itself around the items and to give space for the box to take on damage. Think of it as padding and wiggle room in case the box becomes dented or squished; if the items are too tight in the shipping box, the contents will take the brunt of any damage instead of the dunnage. This applies to most shipping boxes, regardless of cardboard strength. There are plenty of sustainable options for creating cushion that go beyond wasteful air packets or styrofoam. Many of these options are also customizable and can add surface area for more branding or unboxing messaging.

NOTE: Consider the liklihood of dents, dings, scrapes, drags, mud, rain and residue shipping boxes encounter in their journey from A to B. Mottled white boxes are ideal for branding and display opportunities with packaging, but white shipping boxes can be less aesthetically pleasing at delivery than at shipment. Evidence of rough handling could alarm your customer even if the item inside is just fine. Kraft boxes show less cosmetic damage or evidence of environmental stress during shipping. Speaking of environmental stress, mottled white boxes are usually manufactured from bleached paper product and while recycleable, are less environmentally-friendly as biodegradable material and aren't made with as much recycled content as regular kraft cardboard boxes. While white does makes a pretty box, it may not be the best solution for your brand.

Including shipping and handling icons and messages: Create awareness for package handlers by including recognizable icons and messaging to show fragility, density or environmental limitations the packaged items may have. Supplementing shipping box designs with these types of warnings and labels can increase the odds of safer handling during shipping. Adding call to actions to shipping boxes can move customers into a second purchase phase, request reviews or encourage sharing on social media platforms. Read more about shipping and handling icons here.

23 or 32ECT

A standard strength rating for lightweight cardboard boxes based on the Edge Crush Test that can withstand up to 23 or 32 pounds of pressure along the edge of the corrugated material (pressure applied aligned with corrugate direction).

200#

A standard strength rating for heavier duty cardboard boxes based on the Mullen Burst Test that can withstand up to 200 pounds of pressure per square inch of corrugated material.

Carton

Another way to say box, carton is a more generic way to to speak about cardboard or chipboard material containers as opposed to listing out shipping boxes, mailer boxes, shoe boxes, tuck top...etc.

Double Wall

Double wall cartons have two layers of fluted material between two sheets of kraft paper.

Edge Crush Test (ECT)

The Edge Crush Test (ECT) finds the strength of a cardboard box in a stacking scenario. A box of 32 ECT can withstand about 32 pounds of pressure to its edge, or as demonstrated in figure 1.

Figure 1

Flute

Flutes are the wavy corrugated material that make up the thickness of cardboard, or its flute height more specifically.

Figure 2

Kraft

Kraft paper is the iconic brown paper material everyone is very familiar with. Made with paper pulp composite, kraft is easily recycled and is a more sustainable option to bleached, white mottled paper.

Linerboard

The linerboard is the kraft or mottled white paper sheets that sandwiches the corrugated material to create a sheet of cardboard.

Mottled White

Mottled white is the manufacturing description for the paper type that wraps 'white shipping boxes'. Mottled white boxes can be manufactured with both kraft and mottled white interiors.Customboxes.io only provides kraft interior options for mottled white boxes.

Mullen Burst Test

A Mullen Burst Test measures how much force a cardboard sheet can take before bursting. A Mullen-rated box of 200# can withstand 200 pounds of force per square inch. See figure 3 for a visual.

Figure 3

The Mullen test is a better measure for shipping boxes, but shipping methods have improved in the years following its implementation and lighterweight boxes like 23 and 32 ECT have a better chance of success in shipping than historically recognized.

Regular Slotted Container (RSC)

A regular slotted container is no more than a manufacturing term for a cardboard shipping box. Regularly-slotted refers to the common 4-panel flap design found with most shipping boxes.

Single Wall

Single wall cartons have a single layer of fluted material between two sheets of kraft.